7 Essential Issues Fixed by Professional strapping machine repair Services

Wiki Article

Leading Tips for Effective Strapping Machine Repair and Maintenance Practices

Effective strapping machine repair and maintenance is important for operational efficiency in any product packaging atmosphere. By recognizing the machine's components and applying a structured maintenance timetable, organizations can significantly decrease downtime. Regular inspections and appropriate operator training further boost efficiency. Lots of overlook vital methods that can extend devices longevity. Checking out these techniques can expose indispensable understandings for boosting maintenance methods and making sure perfect machine capability.Understand Your Strapping Machine's Components

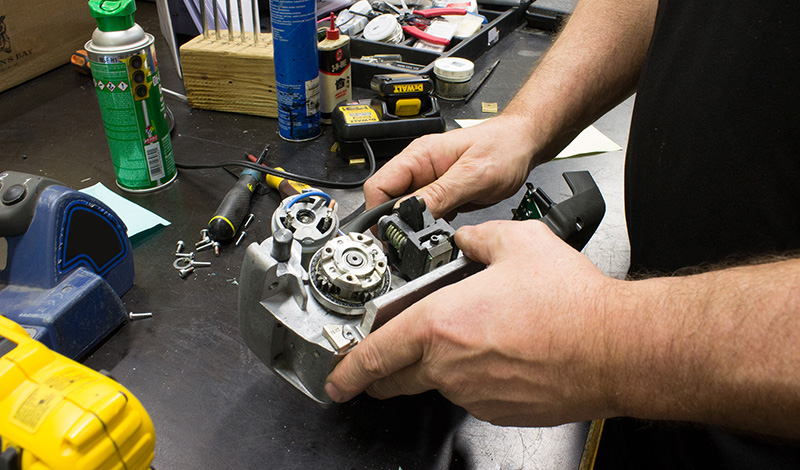

In enhancement to these primary parts, the control board enables operators to establish criteria and keep an eye on the machine's performance. Understanding these components is critical for anyone included in the repair and maintenance of strapping machines, as it allows them to identify issues effectively and implement suitable options. Understanding of each part boosts the total long life and dependability of the equipment.

Develop a Routine Maintenance Arrange

Establishing a normal maintenance timetable is necessary for ensuring the ideal performance and durability of strapping machines. This aggressive method allows operators to anticipate possible concerns before they escalate right into considerable issues. A well-structured routine should lay out particular jobs, such as cleansing, part, and lubrication replacements, in addition to frequency intervals for each task.By sticking to this routine, companies can minimize downtime and boost efficiency. It is advisable to record maintenance activities to track compliance and determine patterns that might suggest underlying issues. Entailing qualified employees in the maintenance process warranties that tasks are finished correctly and effectively.

Including a list can promote extensive inspections and ensure no crucial elements are overlooked. In general, a regular maintenance timetable not just preserves the performance of strapping makers but additionally contributes to a more secure working atmosphere, ultimately bring about reduced functional costs and improved effectiveness.

Conduct Routine Inspections

Performing regular evaluations is necessary for maintaining the efficiency of strapping machines. This procedure includes executing visual devices checks to recognize any noticeable wear or damages, in addition to routine efficiency testing to guarantee peak procedure. By prioritizing these evaluations, drivers can stop possible issues and expand the life-span of the tools.Aesthetic Devices Examine

Regular inspections play a crucial duty in keeping the effectiveness and long life of strapping equipments. Conducting an aesthetic equipment check permits operators to identify noticeable wear, damages, or imbalance that might compromise performance. This evaluation must include analyzing vital components such as bands, rollers, and seals for any type of indicators of fraying, splits, or deterioration. Furthermore, looking for loosened connections and making certain that all safety guards are in location is vital. Inspecting the machine's general tidiness can also protect against debris from impacting operation. Operators should record any type of findings during these visual checks, as this information can direct future maintenance actions and assist in scheduling repair work quickly. Regular aesthetic inspections contribute considerably to avoid major break downs and ensuring smooth procedure.Regular Performance Testing

Regular performance testing is crucial for ensuring that strapping makers run at peak efficiency. This method includes carrying out regular inspections to review the machine's capability and determine any type of potential problems before they rise. Specialists ought to analyze key components such as tensioning, securing, and positioning mechanisms, making sure that each part does according to producer requirements. Surveillance cycle times and output high quality additionally gives useful insights into functional effectiveness. By carrying out a consistent testing schedule, maintenance teams can cultivate aggressive problem-solving, decrease downtime, and prolong the life expectancy of the tools. Additionally, documenting test results permits pattern evaluation, aiding to pinpoint repeating problems and enhance repair strategies. Ultimately, regular performance screening is an essential element of efficient strapping machine maintenance.Use High Quality Strapping Material

Making use of top quality strapping material is crucial for guaranteeing the performance and longevity of strapping equipments. The choice of strapping product directly affects the efficiency of the machine and the honesty of the plans being protected. Poor-quality materials can lead to frequent machine malfunctions, boosted downtime, and the threat of item damage throughout transit. It is recommended to pick strapping materials that work with the details type of strapping machine being used, as this can improve both efficiency and security.Additionally, top quality strapping materials are commonly developed to stand up to various ecological problems, such as temperature level fluctuations and moisture, which helps preserve the reliability of the strapping procedure. Investing in premium products not only lowers the regularity of repair work and maintenance yet also promotes an extra effective procedure overall. As a result, selecting quality strapping material is an essential technique for effective strapping machine maintenance.

Keep the Machine Clean

Maintaining a clean strapping machine is crucial for peak efficiency and long life (strapping machine repair). Dirt, dirt, and debris can build up in time, bring about mechanical failings and lowered efficiency. Regular cleansing prevents the accumulation of contaminants that might hinder the machine's procedureOperators must establish a consistent cleansing routine, concentrating on crucial locations such as the feed system, belts, and rollers. Using proper cleansing agents and tools created for the machine's materials is vital to avoid damage.

Furthermore, evaluating the machine for any type of signs of wear or deposit build-up throughout cleaning can help determine possible issues early. Keeping the strapping machine tidy not only enhances its performance however additionally promotes a much safer working environment.

Address Minor Service Quickly

Dealing with minor repairs promptly is vital for maintaining the effectiveness of strapping devices. Identifying common issues very early and organizing routine assessments can prevent much more significant troubles down the line. Additionally, utilizing top quality substitute components assures that repair work improve the machine's long life and performance.Identify Common Issues

While strapping equipments are developed for durability, they can still come across usual problems that, if left unaddressed, might result in even more substantial problems. Operators should be attentive in recognizing these concerns at an early stage. Frequent issues consist of imbalance of bands, inconsistent stress, and malfunctioning securing mechanisms. These issues can lead to substandard strapping quality and boosted downtime. Furthermore, damage on elements such as rollers and belts can cause functional ineffectiveness (strapping machine repair). Routine monitoring of machine performance permits for timely discovery of these issues. Resolving minor repair services quickly not just boosts the machine's long life however additionally guarantees perfect performance, decreasing the threat of costly breakdowns and production hold-ups. Prompt focus to these usual concerns is vital for reliable maintenanceSchedule Normal Examinations

Routine evaluations of strapping devices are necessary for making certain perfect efficiency and longevity. By scheduling these analyses, drivers can recognize small problems prior to they intensify right into substantial troubles. This proactive strategy permits for timely treatments, lessening downtime and costly repair services. Examinations need to concentrate on elements such as electric motors, belts, and sensing units, guaranteeing they are operating properly. In addition, operators should look for damage on components that might require immediate focus. Resolving small fixings without delay not just enhances the machine's effectiveness yet likewise prolongs its operational lifespan. Establishing a constant examination routine fosters a culture of preventive maintenance, eventually resulting in enhanced productivity and decreased operational disturbances in the lengthy run.Use Quality Substitute Components

Train Your Operators

Educating operators efficiently is essential for the optimal performance of strapping machines. Trained operators can recognize the machine's functions and restrictions, making certain optimum use and lowering the threat of malfunctions. Comprehensive training ought to consist of recognizing operational procedures, safety methods, and fundamental troubleshooting techniques.Regular training sessions can reinforce finest methods and keep operators informed concerning any updates or changes in devices. In addition, hands-on training enables operators to get functional experience, which enhances their confidence and proficiency.

Employing a mentorship program can additionally enhance operator abilities, as seasoned get more info workers can give real-time support and responses.

Including drivers in regular maintenance conversations fosters a sense of ownership, encouraging them to take proactive steps in machine maintenance. In general, purchasing operator training not only enhances machine performance yet additionally causes a much safer working setting.

Record Maintenance and Repairs

Appropriate documentation of repair and maintenance is necessary for reliable strapping machine procedure. Maintaining a considerable maintenance log, tracking repair background, and organizing service documents can considerably boost machine durability and efficiency. These methods ensure that operators have access to important information, advertising educated timely and decision-making interventions.Maintenance Log Relevance

Maintaining a substantial maintenance log is essential for guaranteeing the durability and performance of strapping equipments. This log serves as a comprehensive record of all safety nets, repair services, and examinations done. By documenting maintenance tasks, operators can recognize persisting concerns, thereby assisting in timely interventions before small issues escalate into major failings. A well-kept log additionally assists in compliance with industry guidelines and standards, providing proof of adherence to safety protocols. Furthermore, it enables for better scheduling of maintenance jobs, maximizing machine uptime and performance. Regularly evaluating the log can likewise help in training brand-new employees, ensuring they understand the importance of regular maintenance techniques. Eventually, an efficient maintenance log is an essential device for enhancing operational reliability and performance.Fix Background Tracking

Efficient repair history tracking is necessary for the finest performance of strapping equipments. By thoroughly documenting every repair, operators can identify recurring problems and assess the general dependability of machine components. This organized approach assurances that technicians have accessibility to critical details, such as the nature of previous repairs, components changed, and any alterations made. Additionally, an extensive repair history permits informed decision-making relating to future maintenance techniques and budgeting for extra parts. It likewise aids in adhering to sector requirements and laws that may require documents of devices background. Ultimately, regular tracking of fixings not only improves machine longevity however additionally maximizes operational performance in the facility.Scheduled Service Records

Routinely recording scheduled solution records is vital for making certain the long life and efficiency of strapping makers. These records supply a thorough summary of maintenance tasks, enabling drivers to track the regularity and nature of solutions carried out. By preserving exact logs, companies can identify patterns that may suggest possible issues, assisting in aggressive repairs before considerable failures happen. Scheduled service records also assist in compliance with guarantee requirements and can enhance resale value by showing a dedication to maintenance. Furthermore, they work as a useful resource for specialists during troubleshooting, supplying insights right into the machine's functional background. Eventually, constant documents assists optimize efficiency and minimizes downtime, adding to overall operational performance.Spend in Professional Servicing

Buying specialist servicing for strapping devices is crucial for guaranteeing their durability and height performance. Regular maintenance performed by trained service technicians aids recognize prospective issues before they rise into expensive repair services. Professionals have the competence to conduct thorough inspections, adjust elements, and change used parts using high-grade products.In addition, specialist servicing often consists of cleaning and lubrication, which are vital for preserving the machine's efficiency. This aggressive method not only lowers downtime however also boosts the general productivity of the strapping procedures. Well-maintained tools generally has a much longer life-span, producing better returns on financial investment.

Stay Informed on Market Best Practices

Staying educated on industry finest practices is vital for operators and maintenance groups responsible for strapping makers. Routinely upgraded understanding helps assure the effective operation and durability of tools. Professionals need to engage with industry magazines, participate in workshops, and join online discussion forums dedicated to strapping innovation. By doing so, they can learn more about the most recent improvements, maintenance strategies, and troubleshooting methods.Moreover, connecting with peers can give understandings right into typical obstacles and ingenious solutions. Organizations may also gain from subscribing to newsletters or signing up with organizations that concentrate on packaging and strapping technologies. Engaging with producers for updates on machine specifications and maintenance referrals is just as crucial.

Incorporating this understanding right into day-to-day operations not only enhances machine performance yet additionally reduces downtime and expensive fixings. Ultimately, staying informed empowers groups to carry out best techniques that add to a safer and much more effective workplace.

Frequently Asked Questions

Exactly how Typically Should I Replace My Strapping Machine's Components?

Elements of a strapping machine ought to be replaced based upon usage and wear. Usually, evaluations every six months can assist needed replacements, ensuring perfect performance and protecting against unforeseen breakdowns that could prevent performance. Normal tracking is essential.What Are the Indicators of a Malfunctioning Strapping Machine?

A malfunctioning strapping machine might display indicators such as inconsistent strapping stress, regular jams, uncommon noises, error messages, or noticeable wear on parts. Timely recognition of these issues can protect against additional damages and maintain functional efficiency.Can I Utilize Any Kind Of Strapping Product?

Not all strapping materials appropriate for each machine. Certain equipments require assigned products, such as polypropylene or polyester, to assure peak efficiency. Using the wrong kind might bring about inefficiency and prospective damages.How Do I Appropriately Tidy My Strapping Machine?

To correctly clean up a strapping machine, one need to disconnect power, eliminate particles, and make use of a soft towel with a mild detergent. Routine maintenance warranties peak efficiency and prolongs the machine's life-span, protecting against breakdowns.What Should I Do if My Machine Is Still Under Service warranty?

The owner must contact the maker or accredited dealership for support if the machine is still under service warranty. They can supply guidance on repair work, prospective solution alternatives, and guarantee that guarantee conditions are maintained.Comprehending these elements is critical for any person included in the maintenance and repair of strapping makers, as it enables them to diagnose issues properly and apply proper options. Establishing a normal maintenance routine is vital for guaranteeing the ideal efficiency and longevity of strapping makers. Making use of high-grade strapping material is important for guaranteeing the performance and durability of strapping machines - strapping machine repair. Keeping a considerable maintenance log is necessary for guaranteeing the long life and effectiveness of strapping equipments. Efficient repair history tracking is crucial for the ideal performance of strapping machines

Report this wiki page